What is the CUBITAINER?

In Japan, the CUBITAINER is also known as the "CUBE" or "QB" .

About Products

Molded Liquid Container

CUBITAINER

Synonymous with "bag-in-box," the CUBITAINER is a liquid container which can replace rigid containers, including metal tins, plastic containers and pails. They have been manufactured and sold since 1964.

CUBITAINER is composed of a thin layer of plastic and a cardboard box. The standard type is a mono-material, providing a recyclable solution.

For oxygen sensitive products, we can add the appropriate gas barrier films as well.

CUBITAINER is produced worldwide in Japan, North America and Malaysia.

Product Features

| Containers can be collapsed for ease of storage | The cardboard and container both can be folded and stacked |

|---|

The CUBITAINER saves space significantly compared to metal or rigid plastic containers.

| Easy to handle | CUBITAINER is lightweight compared to metal or rigid plastic containers. Also, through special resin selection, CUBITAINER is very robust and resilient to harsh chemical contents. |

|---|

Various accessories enable a wide range of applications and easy dispensing.

| Reducing waste | The cardboard can be easily recycled and the container can be easily collapsed for disposal |

|---|

A smaller footprint for a lower impact on the environment.

| A clean container |

|---|

The containers are produced through our special molding technology in a highly clean environment

(conforming to the revised Ministry of Health, Labour and Welfare Public Notice No. 380 of the Food Sanitation Act in Japan).

| Made-to-fit |

|---|

The CUBITAINER can be designed to accommodate a wide range of filling equipment from simple semi-automatic to high-speed machines.

Product Specifications

Horizontally scroll for viewing

| Type | Features | Main applications |

| Standard Type | Chemical resistant, high strength Type | Food, Industrial Chemicals, Sodium Hypochlorite, Liquid Processing Agents, Plating Solutions |

| Additive-free Resin Type (Type A) | Additive-free Resin Type | Dairy Milk Products |

| Barrier Type (Type B) | Gas Barrier Type | Sake, Seasoning liquids |

Special Lineup

-

Rectangular 10L, 20L

-

Wide Spouted (45mm) 18L, 20L

-

Wide Handle 5L, 10L, 18L

-

Heat Sealed Types 10L, 18L

Film Liquid Containers

Z-tainer

Z-tainer is an alternative liquid container to rigid, plastic containers, metal containers, and pails.

Designed with safety in mind, the double structure bag-in-box features a gusset-shaped film based pouch.

Assembled to be inside of a cardboard box, this container’s oxygen barrier is a great solution for oxygen-sensitive contents.

For ease of handling, containers over 10L come with a handle hole (with exceptions).

The inner pouch can maximize content evacuation.

Product Features

| Gusset-shaped inner container | Inner container can stand on its own without external cardboard box |

|---|

This is ideal in order not to bring cardboard into cleaner areas of use.

| Handle hole for easier carrying | Handle is located at the top of the inner container |

|---|

Easy to carry by taking it out from the cardboard box.

| Minimizing residual liquid | These pouches have the same evacuation performance as the CUBITAINER |

|---|

Loss of precious contents reduced, thereby contributing to lower cost of ownership.

| Customizable film structures | Film structures that fit various needs |

|---|

By using optimal barrier films, shelf life can be extended and total cost of ownership reduced.

| Easy to automate filling | Easily fed into an automatic filling line |

|---|

This will ultimately reduce the number of people required to operate filling stations, which drives down total cost of ownership.

| Customize | We accommodate your requests |

|---|

We customize the shape, size and structure to meet the product needs. Contact us to get started.

Product Specifications

Horizontally scroll for viewing

| Type | Features | Main applications |

| Standard Type(A-type) | High chemical resistance and robustness | Food and industrial chemicals |

| Low Odor Type (CA type) | Low Plastic Odor | Liquid seasoning |

| High barrier type (B Type) | High gas barrier type | Shochu (distilled spirit) |

| High barrier and low odor (CB Type) | Low odor and gas barrier properties | Mineral water |

Accessories

We have a wide variety of accessories which can be used for both CUBITAINER and Z-tainer

The following accessories can be used for both CUBITAINER and Z-tainer

Disclaimer: These accessories are specifically designed for CUBITINER and Z-tainer. Please refrain from using them for other purposes.

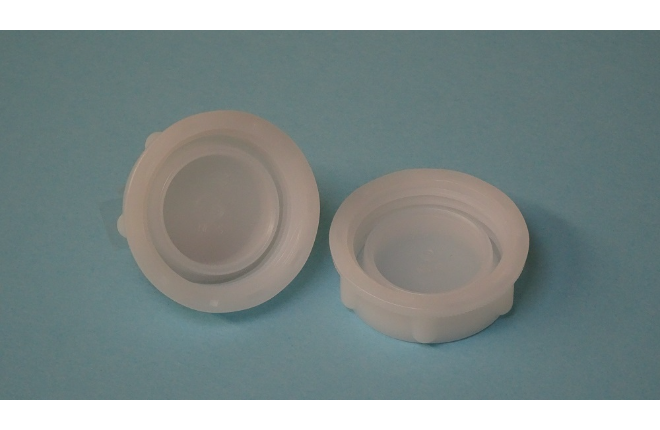

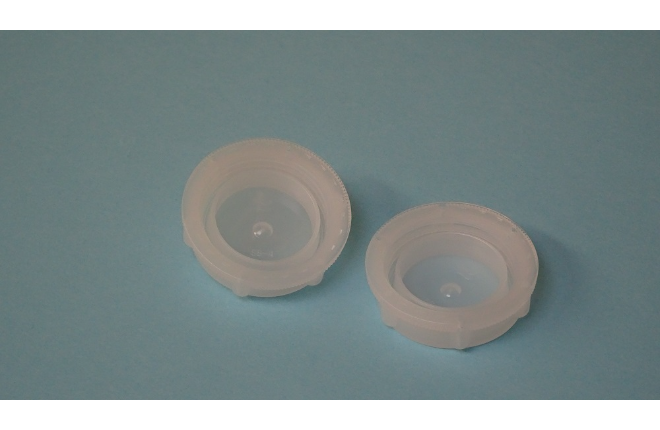

SC CAP

Screw type cap that is one of the most versatile caps.

P CAP

Made of additive-free polyethylene.

DM CAP

Soft material ensures high sealability.

PGC CAP

Optimal for gas-producing liquids. Gas can easily pass outward but liquid is prevented from leaking out.

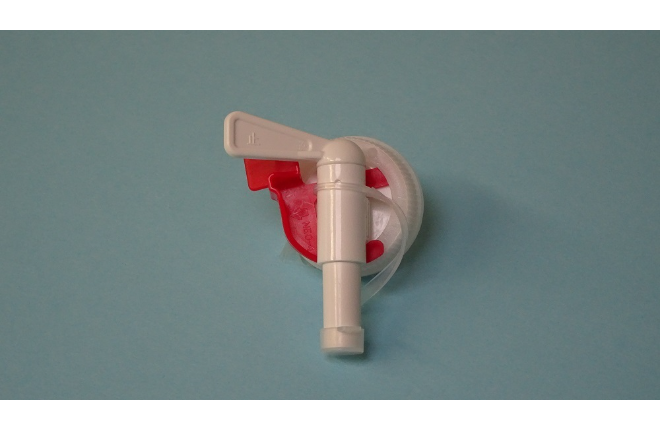

TAP-A

Enables opening and closing and allows controlled dispensing.

TAP-A NEO

Equipped with a handle stopper to prevent unwanted opening. Dispensing remains possible with the handle stopper attached.

TAP-B

Enables quick extraction of highly viscous contents.

ELBOW

Can be connected to the port mouth and facilitates stable liquid dispensing. Collapsible.

Long hose

Expandable hoses.

Product Advantages

Supply Capacity

Production volume of molding type is the highest among the industry. No 1 share in the world. Stable supply is possible.

BCP

Cubitainer® is supplied from multiple manufacturing locations.

Service

ZACROS’ technical staff are readily available to assist, and we can facilitate discussions with equipment manufacturers.

Waste Reduction

Cardboard is highly recyclable and the inner plastic container is made of 150g of resin, which is much less than rigid plastic containers.

Storage

Cubitainer® and Z-tainer® are packaged compactly which enables reduction of storing space.

Barrier Property

We can include barrier films such as EVOH into container film layers according to the product contents. We can help optimize the right barrier for the specific product.

Shielding from Light

Light shielding is provided by cardboard.

Used for hypochlorous acid water which is sensitive to light

Aesthetics

Decorative printing is possible on cardboard (with the use of coated cardboard) for mineral water, wine, etc.

Cleanliness

Inner containers can be taken out from the cardboard by the hanger hold and stand on their own. Therefore, you can take these out before entering cleaner areas to avoid generating extra particles.

Non Rusting

The inside surface is made of polyethylene which has high chemical resistance, making it compatible with many kinds of contents.

The exterior being corrugated cardboard means that unlike metal, it doesn't rust.

Easy to Fill

The Cubitainer® is easy to fill on semi-automatic machines with its unique shape retention, wheras the Z-tainer® is geared more towards automatic filling.

Dispensing

Various accessories help with ease of dispensing such as increasing fluid flow through preventing air displacement.

Easy Capping

The caps are designed to screw-on evenly, which helps avoid unintentional leaking.

Ease of Disposal

The containers can be separated and discarded each into their own category. Cardboard can be recycled, and inner containers only make up 150g of plastic waste.

Price

The cost of the containers varies with quantity purchased.